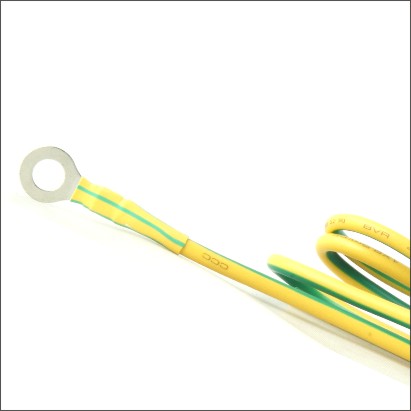

- Stripped color combination designates international electrical grounding

- Flame retardant

- Flexible

- Resists common fluids and solvents

- Continuous operating temperature:-55 ℃ ~125℃

- Shrink Temperature:90 ℃

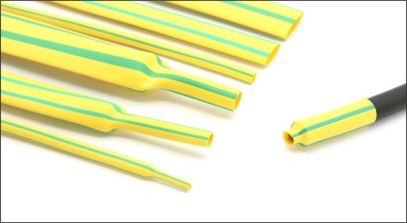

RSFR Tubes

Code: RSFR-(2X,3X)YG

Features

Applications

Yellow/Green Stripped Thin Wall Cross-linked Polyolefin Heat Shrink Tubing

Technical Data

| Property | Test Method | Stantard | Typical Performance |

| Tensile strength ( MPa) | ASTM D 2671 | ≥10.4 | 11.5 |

| Ultimate elongation ( %) | ASTM D 2671 | ≥300 | 450 |

| Tensile strength after heat aged ( MPa) | UL224 158℃×168h | ≥7.3 | 8.5 |

| Elongation after heat aged (%) | UL224 158℃×168h | ≥200 | 350 |

| Dielectric strength ( kV/mm) | IEC60243 | ≥15 | 17.5 |

| Volume resistivity ( Ω·cm) | ASTM D 876 | ≥1X10 14 | 2.5 X 1014 |

Remarks: This data represents average test result and not guaranteed value. Please do not use this value for specification purpose without our consultancy

Other properties

RSFR-(2X)YG

| SIZE | AS SUPPLIED | AFTER RECOVERY | ROUND/FLAT | STANDARD PACKAGE M/spool | |

| mm | INTERNAL DIAMETER Min(mm) | INTERNAL DIAMETER Max(mm) | WALL THICKNESS mm | ||

| 1.0 | 1.5 ± 0.3 | 0.70 | 0.28±0.10 | Round | 200 |

| 1.5 | 2.0 ± 0.3 | 0.90 | 0.30±0.10 | Round | 200 |

| 2.0 | 2.5 ± 0.3 | 1.00 | 0.35±0.10 | Round | 200 |

| 2.5 | 3.0 ± 0.3 | 1.30 | 0.36±0.10 | Round | 200 |

| 3.0 | 3.5 ± 0.4 | 1.50 | 0.38±0.10 | Round | 200 |

| 3.5 | 4.0 ± 0.4 | 1.80 | 0.40±0.10 | Round | 200 |

| 4.0 | 4.5 ± 0.4 | 2.00 | 0.45±0.10 | Round | 200 |

| 4.5 | 5.0 ± 0.4 | 2.30 | 0.45±0.10 | Round | 100 |

| 5.0 | 5.5 ± 0.4 | 2.5 | 0.45±0.10 | Round | 100 |

| 6.0 | 6.5 ± 0.4 | 3.0 | 0.50±0.10 | Round | 100 |

| 7.0 | 7.5 ± 0.4 | 3.5 | 0.50±0.10 | Flat | 100 |

| 8.0 | 8.5 ± 0.5 | 4.0 | 0.55±0.10 | Flat | 100 |

| 9.0 | 9.5 ± 0.5 | 4.5 | 0.55±0.10 | Flat | 100 |

| 10.0 | 10.5 ± 0.5 | 5.0 | 0.55±0.10 | Flat | 100 |

| 11.0 | 11.5 ± 0.5 | 5.5 | 0.60±0.10 | Flat | 100 |

| 12.0 | 12.5 ± 0.5 | 6.0 | 0.60±0.10 | Flat | 100 |

| 13.0 | 13.5 ± 0.5 | 6.5 | 0.60±0.10 | Flat | 100 |

| 14.0 | 14.5 ± 0.5 | 7.0 | 0.65±0.10 | Flat | 100 |

| 15.0 | 15.5 ± 0.6 | 7.5 | 0.70±0.10 | Flat | 100 |

| 16.0 | 17.0 ± 0.6 | 8.0 | 0.70±0.10 | Flat | 100 |

| 17.0 | 17.5 ± 0.6 | 8.5 | 0.70±0.10 | Flat | 100 |

| 18.0 | 19.0 ± 0.7 | 9.0 | 0.70±0.15 | Flat | 100 |

| 20.0 | 22.0 ± 0.7 | 10.0 | 0.75±0.15 | Flat | 100 |

| 22.0 | 24.0 ± 0.7 | 11.0 | 0.80±0.15 | Flat | 100 |

| 25.0 | 26.0 ± 0.7 | 12.5 | 0.90±0.15 | Flat | 50 |

| 28.0 | 29.0 ± 0.7 | 14.0 | 0.90±0.15 | Flat | 50 |

| 30.0 | 31.5 ± 0.7 | 15.0 | 0.95±0.15 | Flat | 50 |

| 35.0 | 36.5 ± 0.7 | 17.5 | 0.95±0.15 | Flat | 50 |

| 40.0 | 41.5 ± 0.7 | 20.0 | 1.00±0.20 | Flat | 50 |

| 45.0 | 46.5 ± 0.7 | 22.5 | 1.00±0.20 | Flat | 25 |

| 50.0 | 46.5 ± 0.7 | 25.0 | 1.00±0.20 | Flat | 25 |

| 60.0 | ≥ 60.0 | 30.0 | 1.10±0.20 | Flat | 25 |

| 70.0 | ≥ 70.0 | 35.0 | 1.20±0.20 | Flat | 25 |

| 80.0 | ≥ 80.0 | 40.0 | 1.30±0.20 | Flat | 25 |

| 90.0 | ≥ 90.0 | 45.0 | 1.50±0.20 | Flat | 25 |

| 100.0 | ≥ 100.0 | 50.0 | 1.65±0.20 | Flat | 25 |

| 120.0 | ≥ 120.0 | 60.0 | 1.70±0.20 | Flat | 15 |

| 150.0 | ≥ 150.0 | 75.0 | 1.70±0.20 | Flat | 15 |

| 180.0 | ≥ 180.0 | 90.0 | 1.75±0.20 | Flat | 15 |

RSFR-(3X)YG

| SIZE | AS SUPPLIED | AFTER RECOVERY | ROUND/FLAT | STANDARD PACKAGE M/spool | |

| mm | INTERNAL DIAMETER Min(mm) | INTERNAL DIAMETER Max(mm) | WALL THICKNESS mm | ||

| 3.2 | 3.2 | 1.0 | 0.55±0.15 | Round | 200 |

| 4.8 | 4.8 | 1.5 | 0.60±0.15 | Round | 100 |

| 6.4 | 6.4 | 2.0 | 0.65±0.15 | Round | 100 |

| 9.5 | 9.5 | 3.0 | 0.75±0.15 | Flat | 50 |

| 12.7 | 12.7 | 4.0 | 0.75±0.20 | Flat | 50 |

| 19.1 | 19.1 | 6.0 | 0.85±0.20 | Flat | 50 |

| 25.4 | 25.4 | 8.0 | 1.00±0.20 | Flat | 50 |

| 39 | 39 | 13.0 | 1.50±0.20 | Flat | 50 |